|

Titanic's

Blueprints

By Roy

Mengot

When David Livingstone of Harland &

Wolff joined the 1996 expedition to the

wreck, he brought with him a set of the

construction plans for the ship to aid him

in his assessments of what he might see

during his dives on the wreck.

These construction plans are available to

the public and show forgotten features of

the ship as well as a look at the work the

builders had done. While the construction

plans are probably not worth the cost to

the general Titanic student, they are

invaluable for the technical student of

the ship, and do shed light on life aboard

Olympic and Titanic for the passengers and

crew, as well as the work done by the

builders.

Most of the plans are drawn in 1/48

scale, resulting in a 20-foot long plan

for most decks and are 3 feet wide. The

original drawings were drawn on linen, not

paper, and the linen fabric texture shows

quite well in many of the copies.

The "Iron" plans show the iron work of

the ship's construction; deck plates,

floor joists, ribs, and structural walls.

They do not show the layout of

non-structural items such as cabin walls.

Interior plans were done separately and,

aside from the basic 'general arrangement'

plans, H&W no longer has these.

Most of the plans are marked simply

"Promenade Plan Nos 400-1" indicating the

hull numbers for Olympic (400) and Titanic

(401). In many areas where a change was

indicated for Titanic, a hand scrawled

note says "401" and the text. The intent

was to maximize the use of the same

drawings on both ships. As it is, some

changes to both Olympic and Titanic were

not fully incorporated back into the

plans. Some references to 433 (Britannic)

appear as well.

Boat Deck

Plan

The Boat Deck iron plan shows a few

interesting oddities. The front of the

bridge overlooking the well deck was

wooden, while the bulwark on either side

going to the bridge cabs was steel. The

bulwark from the backside of the bridge

cabs was change from wood (Olympic) to

steel on Titanic.

The inner cabins on A-deck had skylights.

This was accomplished by placing a

porthole (called a skid light) along the

bottom edge of the officer's quarters,

which let light shine on a 21" skylight in

the inner rooms. In the officer's rooms, a

slanted cover encased this unit and the

officer's bed was probably used to cover

this protrusion into the room.

The photo above was taken on May 31st,

1911 when Titanic was launched and

Olympic was handed over to the White

star line. Note the construction debris

on the deck. Skid lights in the side of

the officer's quarters were part of the

skylights for interior A-deck cabins.

The Illustrated London News photo above

shows a skid light behind Capt. Smith's

leg. The photo is indeed Titanic as the

skid lights on Olympic were oval shaped,

Titanic's were round.

The wheel house was modified during

Olympic's construction. The plan shows a

crude hand drawn curve added to the square

front of the wheel house. The curved front

was incorporated into the ship's

construction. Titanic's wheel house was

further modified to be narrower and

longer, with changes to the front of the

officer's quarters. These Titanic changes

appear as light lines on the plan and you

need to look for them in the linen

texture. No notes are added. Items like

this make it clear that even the builder's

construction plans don't tell the whole

story.

Scuppers

and waterways

All decks on the ship had a 3" camber, or

the center of each deck was 3" higher than

the sides to facilitate the run off of

water, whether from rain or fire hoses.

Streets have a crown in the middle for the

same purpose.

All decks on the outer surfaces had a

waterway (gutter) down the outer edges.

Water ran down the decks to the gutters

and there were scuppers (drains) in the

gutter to channel the water out a

convenient hole. The gutters on the boat

deck and A-deck were 7 inches wide, 13"

wide on B-deck and 15.5 inch wide on

C-deck.

On the upper decks, the drains emptied

down pipes hidden along the pillars of the

lower promenade decks. The drains and

gutters all appear in photos, if you take

time to notice them. The decks were washed

daily to keep the wood tight and to wash

off all the cinders from the funnels.

There's no need having all that ash

tracked back into the ship.

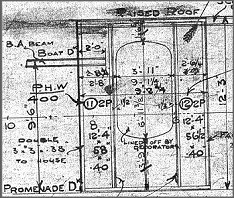

Promenade

Elevation plan

An elevation plan shows side views of the

walls. The A-deck elevation shows the

precise wall, door, and window locations

and sizes. It also has a top view showing

the layout of all the structural walls.

The elevation plan shows the precise

placement of the windows. Shown are the

aft bay windows for the 1st class lounge

on the starboard side. Note the

intricate shading. The 6-8-10 across the

bottom indicate the frame numbers. 2P

8'-11"x21"x.42" indicates two pieces are

needed 8'-11"x21" and .42" thick.

P&S means port and starboard. The

slash marks indicate overlapping joints.

What did H&W use to keep the walls

from squeaking in heavy seas?

A note on the plan says "In way of all

webs, corners, expansion joints, fore end

of deck house, and wherever creaking is

thought liable to take place, one ply of

flannel is to be inserted between iron

connections."

Apparently the area in the lounge pantry

around the aft expansion joint creaked on

Olympic because a note there says, "401

<frame specs> Flannelled!,"

dated 6-2-12. (All dates are written as

day/month/year).

Late

decisions

The front to the weather wall on the

promenade deck with a door and window was

sketched on the plan with a '401' and a

reference to another drawing and dated

14-2-12. In short, this front to the

weather wall was added less than two

months before sailing. Jack Eaton,

co-author of Titanic: Triumph and

Tragedy took great delight in

learning this little fact from the plans

at the Titanic International convention in

April, 2000.

New

cabins.

The plans show the window and entry door

changes for the two added cabins in the

reception area by the aft Grand Staircase,

but not the interior wall arrangement. The

port cabin would be A-37 occupied by Tom

Andrews, and the starboard cabin would be

A-36, occupied by Father Browne as far as

Queenstown.

Web Frames

and d�cor

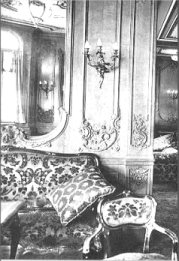

In the 1st class lounge, there are walls

between the bay windows that extend into

the room 9' 1". They are not intended to

divide the room partially into

conversation areas, they are structural

support for the long walls. The nearly 4 X

7-foot hole was added to reduce the

weight.

Since the wall is there, the decorators

took advantage and installed windows or

sunken mirrors. The woodwork then masks

these structures to create conversation

areas.

The 1st class lounge divider walls are

web frames providing support for the

long walls and roof. The decorators used

them to create separate conversation

areas. The inset from the plan shows

that the hole to be added was sized by

the decorators and they inset the

mirrors seen in the photo.

A-deck

iron plan

A small note on the A-deck iron plan

indicates a modification to some ceiling

joints and includes "Approved by Mr.

Andrews" in January of 1912. A number of

small notes on various plans show

technical changes made over Olympic to

simplify or correct problems. They

indicate the level of detail Tom Andrews

dealt with in the ship's construction.

A minor change to the ceiling joists

indicates the approval of Tom Andrews.

This change involved adding strength to

the beams under A-deck around the aft

mast (frames 95-102). This may have been

done to change the vibration

characteristics of the beams. Strength

wasn't an issue here but there may have

been a vibration 'buzz' here on Olympic.

B-deck

Iron plan

The B-deck plan still has the Olympic

layout and doesn't show the elimination of

the B-deck promenade and the changes to

the windows as a result. It was used for

Titanic though as it shows small detail

changes marked '401'. B-deck is the

'strength deck' of the ship as it is the

top of the structural hull. The sides of

B-deck, A-deck and the boat deck are

superstructure and are made of light

weight materials compared to the

structural hull. The expansion joints both

relieve stress imparted to the

superstructure by the flexing of the hull

and prevent the superstructure from acting

as a structural part of the hull. The wall

studs are not integral with the ribs, are

lighter weight, and spaced farther apart

on 4.5' centers.

Shipping

the engines

The engines and boilers were added to the

ship after it was launched and sent to the

fitting out basin. At launch, the uptakes

for the first three boiler rooms were 20 X

45 foot gapping holes that went from the

boat deck to the boiler room floors. The

watertight bulkhead rose in the center of

the hole as high as E-deck. All the

interior bracing for the fan shafts and

vents was added later as well.

For the reciprocating engines, a T-shaped

hole 42 feet long and 38 feet wide was

left through the decks for lowering in the

engine components. After installing the

engines, this hole was filled in by the

decks, the aft grand staircase, and a

light & air shaft to the first class

galley to shrink the hole to 24 X 20 foot

under the tank room on the boat deck.

The turbine engine required a hole 25 X

48 feet and slightly offset to starboard.

After installation, the decks were filled

in to produce a hole 18 X 20 feet for the

uptake to the #4 funnel.

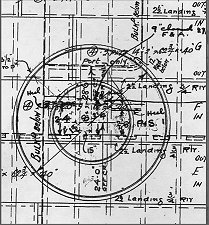

These holes are marked as "shipping

spaces" for the drive train components.

While I mention them here, they appear on

all affected decks.

The shipping spaces were areas in the

decks left open at launch. The holes

were used for lowering the machinery at

the fitting-out quay. These areas would

be finished after the engines and

boilers had been "shipped" through these

spaces for installation. "Bhd below"

indicates a structural bulkhead is

present or will be added on the deck

below.

Titanic appeared as a complete ship to

the casual observer as it was launched. To

a worker on the boat deck, there were five

gargantuan holes that went 10 stories down

to a near hollow keel with a lot of wood

bracing along the sides. These spaces are

clearly marked on the plans.

It does conjure the image of a worker

standing on the engine room floor looking

up a 10-story shaft at a 50-ton cylinder

partially blotting out the sun as it's

lowered.

Bath and

WC

As mentioned, cabin walls are not

structural and are not marked on the iron

plans. Bath and toilet rooms are

structural in that they all have a 3.5-4

inch steel lip (coaming) around the base

of them. Hence they appear on the plans.

Passengers needed to step over these lips

to enter and exit. The same can be seen on

the Queen Mary today.

Pantries, service rooms, and all lavatory

rooms had the steel lip as well. These

make it easy to equate locations on the

iron plans with the deck plans.

Lavatories are structural as they have

a steel coaming (lip) around the base

and appear on the 'iron plans'. Cabins

are not structural and do not appear.

Outer walls for the deck houses are

structural and are shown.

Forecastle

and poop deck

Although still properly part of B-deck,

the forecastle and poop deck are not

included on the B-deck plan. They were

drawn up separately.

The poop deck shows the holes for the

large skylights over the steering engines

just forward of the docking bridge. 3rd

class passengers had a chance to look in

on the big steam engines that turned the

rudder, if so inclined. These were the

only heavy steam machinery visible to any

passenger.

The cranes and capstans are the other

heavy objects indicated on the plans.

Bollards and vents had added supports that

show on the wreck, but not on the plans.

The poop deck plan above shows the

port crane, the forward wall of the 3rd

class smoke room below, the associated

bar bulkhead below, the support girder,

and a jumble of other data. The picture

shows the result of the drawing on

Olympic during her fitting out. Note the

center post supporting the crane. A post

is found under all of the cranes.

C-deck

iron plan

C-deck includes the indoor center of the

ship and areas under the forecastle and

poop deck, and the outdoor well decks.

Lots of

holes

Holes through the decks do not include

small holes for vents and plumbing. These

are shown on other specialized plans.

Stairwells, cargo hatches, light and air

shafts for the galley, cargo hatches, and

the funnel uptakes are the major holes

that provide landmarks.

Under the forecastle are the holes for

the nearly 4-foot diameter mast and two

2-foot diameter holes for the anchor

chains to pass through the deck to the

chain locker below.

The #3 cargo hatch was called the 'Bunker

hatch' on the plans because either cargo

could be stored at the bottom or reserve

coal could be 'bunkered' there.

The crew had a class system similar to

the passengers and it shows on the plans.

Under the forecastle, the seamen used the

'Seamen's stairway' to go down to their

quarters. The firemen, trimmers, and

greasers used the 'Firemen's stairways' to

go to separate quarters in the very bow of

the ship. The firemen had their own mess

hall, the seamen had one too, and the

greasers had a third. These classes of

crew didn't mix together much at all. The

seamen had a bath by their quarters on

E-deck. The boiler crew did not.

C-deck under the forecastle shows the

stairs for the Seamen (center) and the

Firemen (upper right). The 4' hole for

the mast appears in the lower left.

Vertical dotted lines are floor joists.

Horizontal solid-with-dashed lines

indicate overlapping floor plates. Other

deck structures are drawn with solid

lines.

The hole for the dumbwaiter from the 1st

and 2nd class galley to the Ale Carte

restaurant appears on the B and C-deck

plans. Though the restaurant had it's own

galley, the butcher shop and bakery were

in the main galley, and all supplies from

ship's stores were passed up to the

restaurant via the dumbwaiter.

Lack of

holes

As mentioned, B&C decks are the

strength decks that take the greatest

burden of pull-stress as large waves pass

under the center of the ship. In the area

between the 1st and 4th funnels, there are

no stairwells or openings outboard of the

stack uptakes. Both decks have a heavier

gauge stake along side the funnel uptakes

and get thicker going outboard to the

sides. This allows the entire area on

either side of the uptakes to function as

an uninterrupted stress bearing surface.

Some of the German designs featured split

uptakes and other openings outboard of the

center and were prone to cracking the

decks.

The grid

systems

Specific locations in the ship were

marked using various grid systems. For the

overall ship, 'frame numbers' were used. A

frame consists of the ribs on each side of

the ship, the keel beam at the base, and

one floor joist for each deck going up.

The frames are then numbered starting from

the center of the ship and going from 1 to

157 forward, and from 1 to 148 aft.

A location such as the aft wall of the

forward well deck is at '83 fwd'. The

front of the poop deck is at '117 aft'.

You can't calculate distances easily with

this. There is no 'frame 0', just two

'frame 1s' and the frames are not evenly

spaced for the length of the ship. The

spacing is narrower at the bow and stern

and the plans indicate where the spacing

changes occurred. The spacing is of use to

modelers because portholes and doors are

always centered in a frame. Knowing the

frame system allows more accurate

placement of almost everything.

The rows of deck plates are lettered from

a center row 'A' out to row 'H' port and

starboard. Deck plates would be cut and

marked by plate row (or "strake") and

frame number.

Oddly, there are still two rows of plates

past row 'H' that are not marked.

Similarly, shell plate strakes are

lettered A to X from the keel around the

sides up to B-deck. The watertight

bulkheads are labeled 'A' to 'P' working

back from the bow (with no bulkhead 'I')

and the walls to the coal bunkers on

either side of the water tight bulkheads

are lettered 'Q' to 'Z' going back from #6

boiler room.

Rudder

steering gear

The rudder rose to the steering gear room

on C-deck under the poop deck. There is

reinforcement under the deck for the heavy

steam steering engines that turned the

rudder as well as for the rudder mount

itself. All steering commands from the

helm on the bridge were translated to

commands to make the steam steering gear

twist the rudder one way or another. This

was done automatically via cables.

On the wreck today, the poop deck above

seems to have been pushed in and now rests

on top of the steering gear.

E-deck

iron plan

E-deck is the only deck featuring cabins

for all passenger classes and a full mix

of crew.

As a side note, I noticed there were a

number of 3rd class cabins that are

roughly 6 X 7 feet, and had 4 berths. I

suspect we won't see any of these rooms on

any "Titanic II".

The stairway down to the squash court

shows a modification dated Feb. 8, 1910. A

stairway that would have been steep down

the backside was crossed out and a new

arrangement is just drawn over the plan.

They couldn't erase things easily on the

plans and they were not going to redraw

them.

Changes to the drawings were done by

simply crossing out the old and

redrawing the new. The stairs to the

squash court were modified from a steep

drop down the back of the court to a

longer wrap-around arrangement. The tiny

escape hatch from #6 boiler room is seen

at upper left.

Escape

from below

E-deck is the top of the forward

watertight bulkheads and you find escape

shafts for the crew in the lower spaces.

One is located at the front of #6 boiler

room (upper left in the drawing above).

It's 24 X 30 inches and would contain a

42-foot ladder up this tiny shaft.

Personnel in the boiler room used it

following the collision to get out.

Four more such escape shafts appear for

the compartments of the generator room,

the #5 and #6 cargo rooms, and the aft

propeller shaft spaces.

Scotland

Road

"Scotland road was the main hallway that

ran most of the length of the ship. In

addition to connecting the forward 3rd

class to the after 3rd class, and to their

dinning room in the center, it was the

main travel path for all the crew that

served the passengers.

The plans show that for most of its

length, it's about 8 feet wide and has

7-inch wide gutters (waterways) going down

both sides. These gutters would have given

a more 'alley way' look to it. Besides the

hundreds of crew and all of 3rd class

using Scotland Road to get about, food was

moved to the forward grew galley via this

route from ship's stores. Were the gutters

there so they could just hose it down at

regular intervals?

There were 5-foot square trap doors in

the floor for shipping (replacements?)

furnaces down to the boiler rooms. These

would be brought in through the numerous

doors in the side of the ship on E-deck.

In the center of the ship, there are 5

baths for the 250 or so stewards and

galley staff. 3rd class passengers

wandering the hall or going to and from

meals probably got to see the staff

wandering to and from the baths and

lavatories in their robes. For all of 3rd

class, there were just two baths located

aft most on D-deck.

In Cameron's "Titanic", Rose uses

Scotland Road to rescue Jack from the

Master at Arms office. While the plans

don't show plumbing, the overhead hanging

pipes were probably there as well, adding

additional charm to the d�cor.

The

engineer's mess

As mentioned, there was a class system

for the ships crew and the engineers were

pretty much first in the pecking order.

The engineer's mess was half the size of

the firemen's mess for 1/10 the people. It

was one flight up from their rooms and the

food came down one flight from the 1st/2nd

class galley on a dumbwaiter. The plans

only show the stairway down and the

footings to the dining room and pantry.

By contrast, all of the stewards and

staff serving the passengers had no dining

room at all. They grabbed a plate of stuff

in the galley and ate where they stood

before going about their duties.

G-deck

iron

G-deck is different in that they only

draw the port 2/3 of the ship. The

starboard 1/3 is assumed to be a mirror of

the port side unless indicated in notes.

The refrigerated storage rooms for the

ship's groceries are indicated aft as well

as the base of the squash court and the

area of the 3rd class open births forward.

Dealing

with coal

The plan throws a great deal of light on

the business of moving coal around. The

coaling doors above were used to drop in

the large chunks of coal that were

normally delivered to ships. G-deck formed

a shelf around the boiler rooms and was

the work space for breaking up the coal.

The big chunks needed to broken up into

smaller pieces by the trimmers for easier

shoveling by the firemen.

The broken coal was thrown down holes in

the deck into the 24-foot deep coal

bunkers. The trimmers then cross level the

coal across the roughly 90-foot of the

bunker to keep coal ready for use at the

boilers.

Trimmers literally went to work by

dropping through a hole in G-deck and

started manhandling coal. The trianle

shaped trimmer's hole in the drawing

above opened to the aft port coal bunker

in #6 boiler room. Consider also that

boiler rooms are hot and clammy.

The tank

top iron plan

The tank top was the floor above the keel

in that the multi-cellular bottom of the

ship was bounded by the keel and tank top.

The bilge and ballast tanks were

sandwiched between the two, as well as a

great deal of plumbing. In all of the

machine spaces, there was a raised working

floor and more pipes ran between the tank

top and the raised floor. There were

simple trap doors in the raised floor to

allow access to the tank top. To enter the

cellular bottom, the tank top had a large

number of manhole covers that were bolted

down, permitting the double bottom to

remain water tight.

The tank top was the of the ship from the

dynamo room to #6 boiler room. Fore and

aft of that, the tank top surface was a

narrower wedge and the frames of the ship

extended out along the keel to the sides.

The sides of #3 bunker hatch were open and

additional coal was dumped between the

frames and rested on the keel plates

themselves.

Other

plans

There are a large number of plans needed

to design a great ship and this article

has touched on the major deck plans. Other

plans studied include:

The lines plan which shows the

contours of the ships hull. This is very

useful for a modeler trying to accurately

reconstruct the shape of the hull.

The plating plan shows the side

plates, portholes, bilge keel, and

fittings such as mooring cleats in the

side. The port side of the center anchor

well was a removable plate. The sides were

not uniformly 1" thick. Fore and aft of

the funnels, the side plates papered down

slowly .7" and even .6". As these areas of

the ship had less buoyancy than the wider

center of the ship, it was necessary to

reduce the weight at the ends to avoid

load stress. To compensate somewhat, the

ribs were spaced closer together at the

very bow (2' on center) and at the stern

(27" on center).

The three watertight bulkhead plans

show all the water tight bulkheads

including all the structural support.

Higher decks had lighter studs and lower

sections were supported with I-beams to

account for water pressure at varying

depths should the compartment be flooded.

The bulkheads were not uniform straight

walls. In several places, the bulkhead on

a given deck will be shaped, offset, or

molded around something. This required

decks in offset areas to require

watertight caulking as well as the

bulkheads. Watertight bulkheads were only

caulked on one side.

The engine room columns plan

shows all the columns and the associated

steel work in the engine rooms. This would

be a must-have plan for someone doing a

model of just the engine rooms as it shows

details of all the columns, beams, upper

engine room wall details, and other

information not shown in the engine room

schematics.

The mid-ship cross section shows

the different sizes and thicknesses of the

decks, girders, web frames, cellular hull

dividers, etc. The does show plate

thicknesses in details not found on many

of the deck plans.

The expansion joint detail shows

all of the smallest details about the fore

and aft expansion joints including how the

planking was framed and the construction

at the sides and on the deck houses. The

joints were covered with a leather cover

that had a small drain hole at the base.

At B-deck, the outer strake of deck on

B-deck (stringer strake) was doubled 1"

plates. The top most strake of the sides

(shear strake) was double 1" plates as

well. These were joined together with a

.9" L-beam to produce a top edge to the

structural hull that was 3 inches of steel

on the lattice of the frames. In contrast,

the sides of B-deck were superstructure

built of 1/4" plate on lightweight studs

tacked to the top of the structural hull

and spaced farther apart. The purpose of

the expansion joint was to relieve the

superstructure of the stress of the

bending forces being carried by the

structural hull.

Conclusions

Four years of architectural drafting I

had in high school served me well in being

able to read the plans.

Understanding the ship's plans puts

photos of the ship's construction in a new

light. They provide a link to the men who

drew and read them and moved iron and wood

to realize the plans in a finished ship.

Many of their hand written notes still

adorn the plans, perhaps even by the hand

of Tom Andrews.

The plans also highlight or indicate

features of the ship that were part of

daily life for the crew or passengers but

were lost of forgotten in the books by

noted authors that we all have read.

Hopefully this sampling from the plans

underscores how much information is still

available about the ship and what we can

still learn about the people who built and

sailed on Olympic and Titanic. They're

trying to tell us the story, ya just gotta

sit and listen.

About the Author

Roy Mengot is a defense systems engineer

with Raytheon Systems Company in Dallas,

Texas. He's studied the Titanic at

Woodshole and other sources and built a

model of the wreck that won 'Best in show'

at the 1997 International Modeler's

Society convention. He was just named as a

member of the Marine Forensic Panel of the

Society of Naval Architects and Marine

engineers.

Visit his web site on the wreck at www.flash.net/~rfm/.

|